Die casting is one of the most versatile processes for producing engineered metal components. It offers a number of advantages over many other metal forming processes such as superior dimensional accuracy and stability, high speed production, and lower production costs.

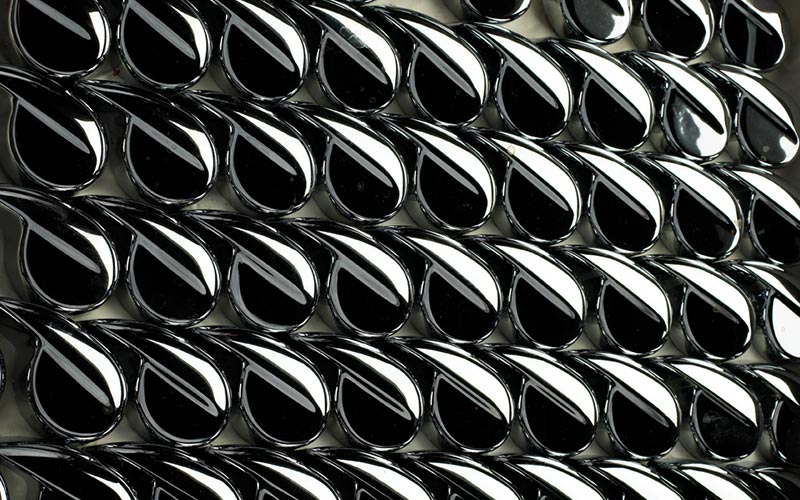

You’ll benefit from our advanced high pressure casting capabilities. Our casting technologies include fully automated metal delivery, automated die spray, robotic part extraction, and computer controlled casting machines with automatic rejection of castings which haven’t met key parameter inputs. We’ve made the investment in these technologies over the years so you can be assured of receiving the highest quality innovative components designed to meet your specific product objectives and standards.

Another advantage you’ll appreciate with Fort Recovery Industries is our unique ability to provide cost competitive secondary processes. These include in house custom machining, CNC machining, finishing, buffing, electroplating, powder coating, pad printing, injection molding, and assembly. As a result, you receive the finished components you require in one efficient step. You benefit with our superior control of secondary operations, faster turnaround, and reduced shipping costs because Fort Recovery Industries handles it all.

The advanced capabilities and resources you’ll find at Fort Recovery Industries have grown significantly over the years due to our commitment to responsiveness.