PRODUCT ENGINEERING

Superior part designs take into account the precision required to meet the requirements of form, fit, and function in order to achieve the most cost effective product cost and to maximize tooling life. We apply the latest NADCA (North American Die Casting Association) casting design principles with design considerations including: parting line location, moving die components (slide actions), required tolerances, machined surfaces, finishing requirements, and secondary/assembly operations. Fort Recovery Industries can participate in, or lead the product design development. We use 3D part modeling software to develop and communicate product design information to accelerate the design process.Customers benefit from our engineering support services so that targeted results are achieved. These services, to name a few, can be used at any time throughout the product life cycle:

Superior part designs take into account the precision required to meet the requirements of form, fit, and function in order to achieve the most cost effective product cost and to maximize tooling life. We apply the latest NADCA (North American Die Casting Association) casting design principles with design considerations including: parting line location, moving die components (slide actions), required tolerances, machined surfaces, finishing requirements, and secondary/assembly operations. Fort Recovery Industries can participate in, or lead the product design development. We use 3D part modeling software to develop and communicate product design information to accelerate the design process.Customers benefit from our engineering support services so that targeted results are achieved. These services, to name a few, can be used at any time throughout the product life cycle:

- CAD Design (Pro/Engineer ®, Pro/Manufacture ®, Solidworks ®, AutoCAD ®)

- Prototyping: ABS Printed Models, actual HPDC samples using P20 tool steel (sometimes referred to as soft tooling), Spin Castings, Sand Castings

- CNC CMM measurements

- APQP launch format including: DFM & Producibility Process, PFMEA, Flow Charts, Gantt Charts, Control Plans, Layouts, Capability Studies, etc).

- VA/VE activity involvement

- DOEx development

TOOLING

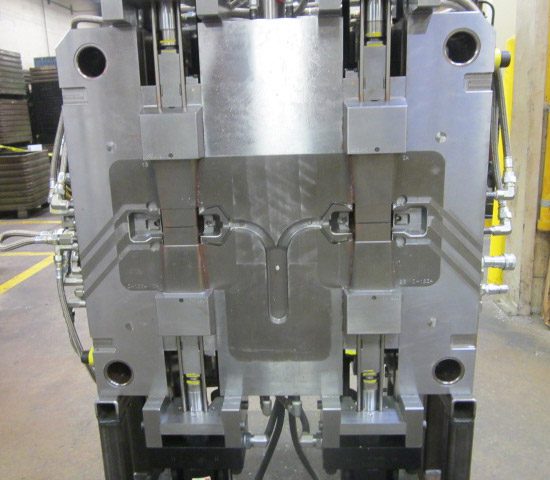

Tooling design is an integral part of producing a quality product. A properly engineered die cast tool with an optimized part design will assure part accuracy and extend the die life. Therefore, we highly recommend that we become involved in the development cycle of your part as early as possible so that all product launch goals can be achieved for all participants.

Tooling design and construction includes:

- Domestic and LCC tooling capabilities

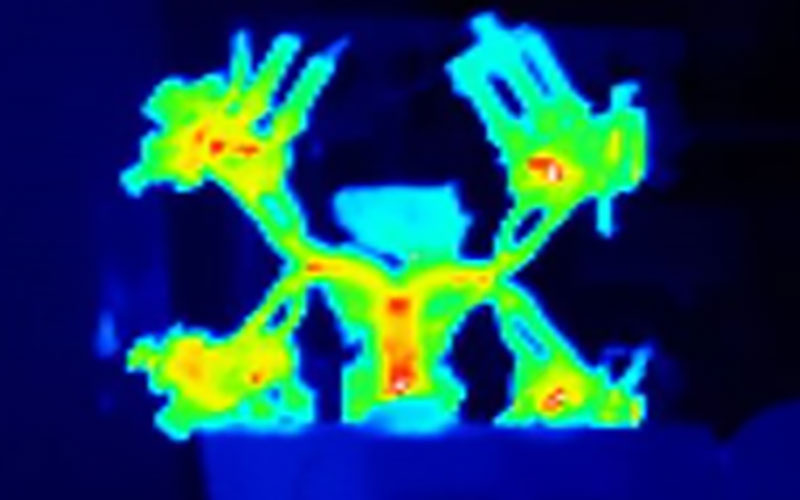

- Flow Simulations using Flow-3D ® software

- Superior tool materials and heat treat practices

- Special die coatings when warranted

- Local tool design, construction, and repair services

- Comprehensive Tooling Standards and Tool Design Checklists

- Formal tool maintenance and tool asset administrative support

- Shot count tracking

Our Engineering support services applies practical methods to achieve targeted results, helping to ensure the quality and success of your products at an early stage.